Why Remote Diagnostic Services Are Revolutionizing How We Monitor and Fix Everything

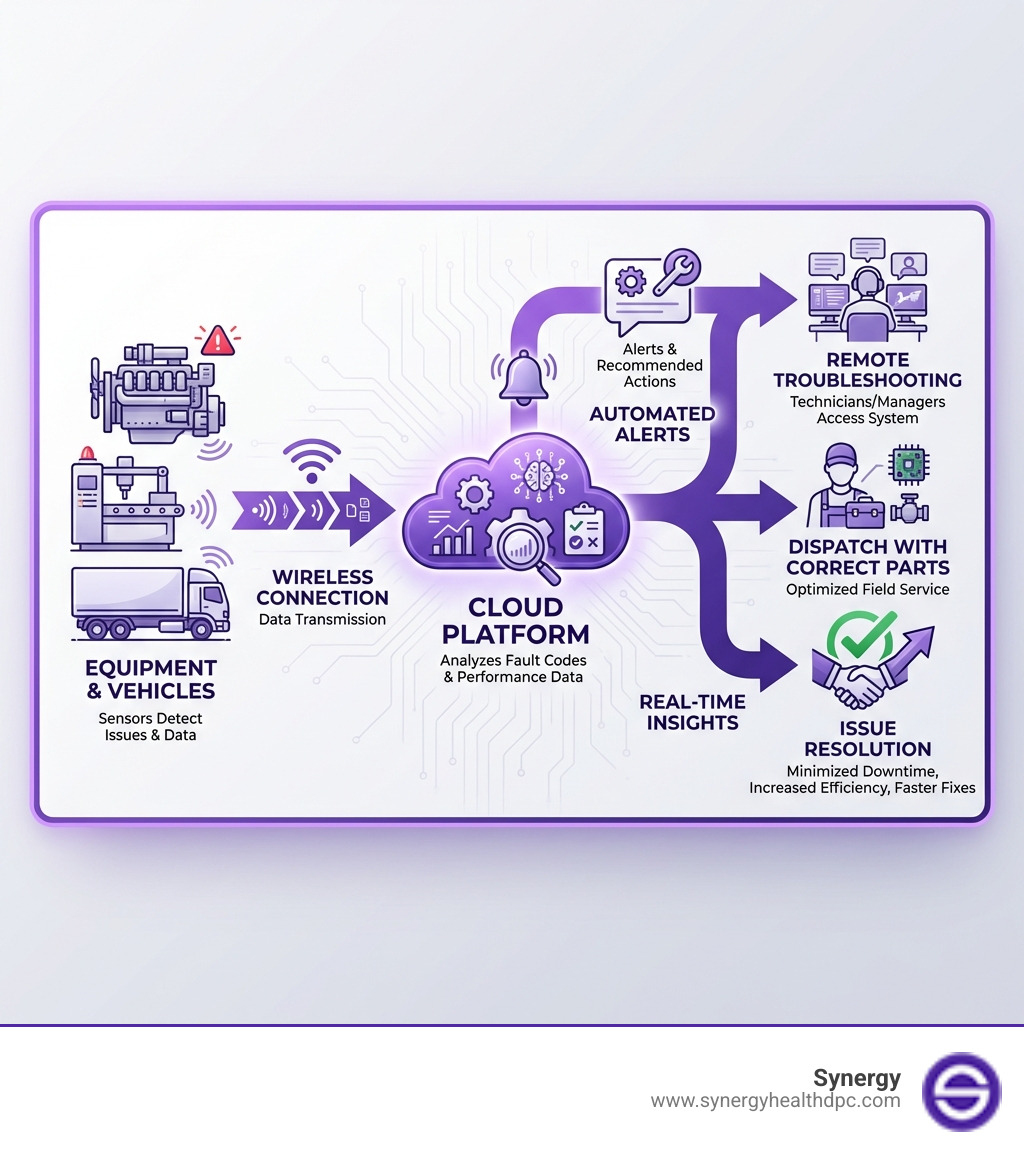

Remote diagnostic services enable technicians, fleet managers, and healthcare providers to monitor, troubleshoot, and fix problems from anywhere—without an onsite visit. By connecting equipment, vehicles, or patients to cloud-based platforms through sensors and telematics, these systems detect issues in real-time, alert the right people, and often resolve problems before they cause downtime or emergencies.

What Remote Diagnostics Do:

- Monitor equipment or vehicles continuously using IoT sensors and wireless data transmission

- Detect faults and anomalies through automated analysis of fault codes and performance data

- Alert technicians or providers instantly when issues arise, often with recommended actions

- Enable remote troubleshooting so many problems are solved without a site visit

- Reduce downtime and costs by catching issues early and ensuring the right parts arrive on the first visit

The shift toward remote diagnostics is not just a technological upgrade—it’s a fundamental change in how we approach maintenance, repair, and care. Traditional models meant waiting for something to break, dispatching a technician without full information, and hoping they brought the right tools. Blind dispatches represent a huge field service cost for organizations, often requiring multiple visits and causing extended downtime.

Today, remote diagnostics flip that script. A truck driver hundreds of miles from home base no longer needs to guess what’s wrong when a check engine light appears. An HVAC system in a commercial building can alert facility managers to a failing component before tenants complain about temperature swings. A healthcare provider can assess a patient’s symptoms through a virtual visit, determining whether they need urgent care or simple home treatment—all without the patient leaving their couch.

The numbers tell a compelling story. Organizations implementing remote diagnostic systems report up to 92% first-time fix rates, 50% fewer onsite repair visits, and 3x faster issue resolution. In HVAC alone, 15-30% of energy consumption may be wasted due to system faults and improper controls—problems that remote monitoring can catch and correct.

Whether you’re managing a fleet of trucks, maintaining complex industrial equipment, or seeking accessible healthcare, remote diagnostics deliver the same core promise: visibility, speed, and control.

What Are Remote Diagnostics and How Do They Work?

Imagine having a crystal ball that tells you exactly what’s wrong with your machinery, vehicle, or even your own health, all without having to be physically present. That’s the magic of remote diagnostic services. At its core, remote diagnostics involves monitoring and analyzing the performance and health of systems from a distance. This is achieved by leveraging a combination of cutting-edge technology that connects the physical world to digital intelligence.

The process typically begins with sensors embedded within equipment or vehicles. These sensors continuously collect vast amounts of data—everything from temperature and pressure to vibration, fault codes, and operational metrics. This data is then transmitted wirelessly, often via cellular networks (like 4G/5G) or Wi-Fi, to a central cloud-based platform. Once in the cloud, sophisticated software analyzes this incoming data in real-time, looking for anomalies, patterns, and specific fault codes that indicate potential issues.

This system acts like a vigilant digital guardian, constantly checking the pulse of your assets. When a problem is detected, it automatically triggers alerts, notifying the relevant personnel—whether that’s a fleet manager, a maintenance technician, or a healthcare provider. This real-time monitoring and data analysis form the backbone of how remote diagnostic services enable proactive management and rapid response.

The Technology Behind Remote Connections

The seamless operation of remote diagnostic services relies on several key technological components working in harmony:

- IoT Sensors: These are the eyes and ears of the system, embedded in everything from engine components to HVAC units and even wearable health devices. They measure various parameters and convert them into digital data.

- Edge Computing: Sometimes, initial data processing happens directly on the device or gateway (at the “edge” of the network) before being sent to the cloud. This reduces latency and bandwidth usage, allowing for quicker local decision-making.

- Secure Data Gateways: These devices act as intermediaries, collecting data from multiple sensors and securely transmitting it to the cloud. They often handle data encryption and protocol translation.

- Wireless Communication (4G/5G): High-speed, reliable wireless networks are crucial for transmitting large volumes of data quickly and consistently, especially for mobile assets like trucks or remote equipment.

- GPS Tracking: For vehicles and mobile assets, GPS data provides essential context, allowing for location-based diagnostics, routing to service centers, and understanding operational environments.

These technologies combine to create a robust infrastructure for Remote Diagnosis and Troubleshooting, ensuring that information flows efficiently and securely from the asset to the diagnostic platform.

The Diagnostic Process from Start to Finish

Let’s walk through a typical remote diagnosis session to see how these pieces fit together:

- Data Collection: Sensors on the asset (e.g., a truck engine, an HVAC compressor) continuously gather performance data and monitor for fault codes.

- Transmission: This data is sent via a telematics device or gateway over a secure wireless connection to a cloud-based diagnostic platform.

- Fault Code Analysis: The cloud platform processes the incoming data, identifies any active fault codes, and analyzes performance metrics against historical data or predefined thresholds.

- Automated Alerts: If an anomaly or fault is detected, the system generates an immediate alert, often categorized by severity, and sends it to the relevant personnel (e.g., fleet manager, technician, facility manager).

- Remote Troubleshooting: A technician or specialist can then remotely access the diagnostic platform to view detailed information about the issue, including the fault description, its severity, and potential causes. In some cases, they can even perform remote tests or adjustments.

- Technician Dispatch (if needed): If the issue cannot be resolved remotely, the system helps in dispatching a technician. Crucially, because of the prior remote diagnosis, the technician arrives with a clear understanding of the problem and often the correct tools and parts needed for a first-time fix.

This systematic approach minimizes guesswork and maximizes efficiency, fundamentally changing how we identify and resolve issues.

The Transformative Benefits of Remote Diagnostic Services

The accept of remote diagnostic services isn’t just about adopting new technology; it’s about open uping a new era of operational excellence. The benefits ripple across every aspect of an organization, from the bottom line to customer satisfaction.

We’re talking about a significant leap forward, moving away from reactive problem-solving to a proactive, data-driven approach. This shift leads to:

- Reduced Downtime: Catching issues before they become critical failures means less time equipment spends idle.

- Cost Savings: Fewer emergency repairs, optimized labor, and extended asset lifespan all contribute to significant financial benefits.

- Increased Efficiency: Streamlined workflows, informed decision-making, and faster resolution times make operations smoother.

- Improved Safety: Proactive identification of potential failures can prevent accidents and ensure safer operating environments.

- Improved Customer Satisfaction: Less disruption, quicker service, and more reliable operations lead to happier customers.

Reducing Downtime and Operational Costs

One of the most compelling advantages of remote diagnostic services is their ability to slash downtime and operational costs. We all know that unexpected breakdowns are a budget’s worst nightmare. They lead to lost productivity, expensive emergency repairs, and often, the need for multiple, costly onsite visits.

With remote diagnostics, we turn this scenario on its head. Issues are identified early, often before they manifest as a noticeable problem. This allows for scheduled maintenance, turning a potential crisis into a manageable repair. Organizations leveraging these services report 50% fewer onsite repair visits, translating directly into reduced travel costs, labor hours, and vehicle wear and tear.

Furthermore, the ability to diagnose remotely means that when a physical visit is unavoidable, the technician arrives with a complete understanding of the problem and the right parts in hand. This eliminates the dreaded “blind dispatch” and the need for follow-up visits, reducing both time and expense. This proactive approach not only prevents costly repairs but also extends the operational life of assets, making every dollar invested in equipment go further. It’s similar to how The Benefits of Virtual Healthcare reduce the burden on traditional clinics and save patients time and money.

Improving First-Time Fix Rates and Technician Workflow

Think about it: what’s more frustrating than a technician showing up, scratching their head, and having to leave to get a part or consult a manual? Remote diagnostic services make that a thing of the past. Our research shows that companies adopting these solutions achieve up to 92% First Time Fix Rate. This incredible statistic is a testament to the power of pre-diagnosis.

Before a technician even sets foot on-site, they have access to a wealth of diagnostic information. They know the specific fault codes, the history of the asset, and often, the exact parts required. This means:

- Pre-diagnosis: Technicians arrive prepared, knowing the root cause before they even open their toolbox.

- Correct Tools and Parts: No more guessing games. The right equipment and replacement parts are brought on the first visit, avoiding costly delays and return trips.

- Optimized Scheduling: With better insight into repair complexity, service calls can be scheduled more efficiently, leading to shorter wait times and better resource allocation.

This level of preparation not only saves time and money but also significantly boosts technician morale and productivity. They can focus on solving the problem, rather than diagnosing it from scratch. This improved workflow is a game-changer for field service operations, as detailed in discussions around Remote Machine Diagnostics and Root Cause Analysis. Just as telehealth offers Category: Benefits of Telehealth by streamlining patient care, remote diagnostics streamlines equipment maintenance.

Remote Diagnostics in Action: Applications Across Industries

The beauty of remote diagnostic services lies in their versatility. While the core principles remain the same – collect data, analyze remotely, act decisively – their application transforms operations across an astonishing array of industries. From the roar of a truck engine to the quiet hum of an HVAC unit and the critical monitoring of human health, remote diagnostics are proving to be indispensable.

We’ve seen how this technology can be a universal problem-solver, adapting to the unique challenges of each sector. Let’s explore some of the most impactful use cases.

Automotive and Trucking Fleets

For the automotive and trucking industries, where vehicles are often hundreds or thousands of miles from their home base, remote diagnostic services are nothing short of revolutionary. Truck maintenance is a huge concern, and breakdowns can lead to major downtime and unexpected costs. Before remote diagnostics, a check engine light meant a driver might have to pull codes themselves, or a company would dispatch a new truck to pick up a broken-down truck’s load, incurring extra labor and delays.

Now, with solutions like JPRO Diagnostic Software and similar technologies, fleet managers can:

- Fleet Health Monitoring: Continuously track the health of individual vehicles and entire fleets. Telematics devices transmit fault codes, performance data, and GPS information to a central system.

- Predictive Maintenance Scheduling: Identify potential issues like engine, brake, or transmission problems before they lead to critical failure, allowing for repairs to be scheduled during planned downtime. This significantly reduces vehicle downtime.

- Fuel Efficiency Analysis: Monitor active issues that might lead to higher fuel costs and address them proactively.

- Reduced Vehicle Downtime: By catching issues early, we can avoid unexpected failures and keep trucks on the road, ensuring a 3x faster issue resolution compared to traditional methods.

Even specific operations, like ADAS calibrations or complex programming, can be supported remotely, ensuring vehicles are safely back on the road quicker. Companies like Tesla also use remote connections, allowing owners to authorize diagnostic access for repairers, retrieving error codes and live signal data to streamline service.

HVAC and Building Management

In heating, ventilation, and air conditioning (HVAC), efficiency and reliability are paramount. Remote diagnostic services are changing how buildings manage their climate control systems, leading to significant energy savings and improved tenant comfort.

Studies have shown that 15-30% of HVAC energy consumption may be wasted due to system faults and improper controls. That’s a staggering amount of wasted energy and money! Remote diagnostics helps us tackle this head-on:

- Energy Consumption Monitoring: Continuous online monitoring identifies performance irregularities that could lead to increased power consumption.

- Fault Detection: Minor issues that might otherwise go unnoticed are flagged immediately, preventing them from escalating into major, costly breakdowns.

- Tenant Satisfaction: By proactively addressing HVAC issues, we can ensure consistent climate control, leading to fewer complaints and a more comfortable environment for occupants.

This proactive approach means technicians can often diagnose problems remotely, arrive with the correct parts, and resolve issues in a single visit, minimizing disruption and extending the lifespan of complex HVAC systems.

Healthcare and Telemedicine

Perhaps no sector has seen a more profound shift towards remote capabilities than healthcare, especially with the rise of telemedicine. Remote diagnostic services in healthcare empower us to provide more accessible, prompt, and personalized care, aligning perfectly with Synergy Health DPC’s mission.

Our virtual primary and urgent care services leverage the principles of remote diagnostics to offer:

- Virtual Consultations: Patients can connect with providers for unlimited virtual visits, allowing for initial assessments, symptom analysis, and treatment planning from the comfort of their homes. This is a prime example of Accessible and Prompt Healthcare at Your Fingertips.

- Remote Patient Monitoring: While not always direct diagnostics in the traditional sense, the continuous monitoring of vital signs or chronic conditions through connected devices allows providers to “diagnose” trends or anomalies from afar, intervening proactively.

- Rapid Diagnostics for Patient Care: For many common ailments, a virtual appointment can lead to a quick diagnosis and treatment plan, avoiding unnecessary trips to urgent care or the ER. This allows for quicker decision-making on whether an in-person visit is truly necessary or if a remote solution is sufficient.

By offering 24/7 provider access and personalized treatment with no copays for a single monthly fee, Synergy Health DPC embodies the benefits of remote healthcare diagnostics. Our services, facilitated by virtual appointments, ensure that patients receive timely care and expert advice, making healthcare more convenient and effective. Explore more about how we facilitate Tag: Virtual Appointment options.

Key Features, Security, and Choosing the Right Solution

Implementing remote diagnostic services is a strategic investment, and choosing the right solution is paramount. It’s not just about getting data; it’s about getting actionable data, securely, and in a way that integrates seamlessly with your existing operations. We need solutions that are scalable, intuitive, and provide comprehensive reporting capabilities. For deeper insights into selecting such solutions, you might find valuable information on Viam’s remote troubleshooting solutions.

Essential Features of Effective Remote Diagnostic Services

When evaluating remote diagnostic services, we look for a suite of features that empower proactive management and efficient problem-solving. Here’s a checklist of must-haves:

- Real-time Data Visualization: A clear, intuitive dashboard that displays live performance metrics, fault codes, and asset status at a glance.

- Historical Data Analysis: The ability to review past performance, identify recurring issues, and track trends over time to understand root causes.

- Customizable Alerts and Notifications: Configurable alerts based on specific thresholds or fault codes, delivered via email, SMS, or in-app notifications.

- Bi-directional Controls: For some applications, the ability to remotely initiate tests, adjust settings, or even update software (over-the-air updates) is incredibly powerful.

- Comprehensive Reporting: Detailed reports on asset health, maintenance history, cost savings, and operational efficiency.

- Integration Capabilities: Seamless integration with existing fleet management systems, enterprise resource planning (ERP) software, or customer relationship management (CRM) tools.

- Scalability: The solution should be able to grow with your needs, accommodating more assets and users without compromising performance.

- User-Friendly Interface: An intuitive design that allows technicians, managers, and even non-technical staff to easily access and understand critical information.

- Mobile Accessibility: Access to dashboards and alerts via mobile devices for on-the-go monitoring and response.

These features collectively ensure that a remote diagnostic system is not just a data collector, but a true operational asset.

Security Best Practices for Remote Diagnostic Systems

The thought of remotely connecting to critical systems can raise valid security concerns. We understand that data integrity, privacy, and system protection are non-negotiable. Therefore, robust security measures are paramount for any remote diagnostic services.

Here are some best practices we advocate for:

- Data Encryption: All data transmitted between assets, gateways, and the cloud platform must be encrypted using industry-standard protocols to prevent unauthorized access.

- Secure Access Control: Implement strong authentication methods (e.g., multi-factor authentication) and granular role-based access control (RBAC) to ensure only authorized personnel can access specific data and functionalities.

- User Authentication: Require unique, strong credentials for all users and enforce regular password changes. For vehicle diagnostics, systems like Tesla’s require explicit owner authorization for diagnostic access, adding an extra layer of security and control.

- Regular Security Audits: Conduct periodic vulnerability assessments and penetration testing to identify and address potential weaknesses in the system.

- Compliance Standards: Ensure the system adheres to relevant industry-specific regulations and data privacy laws (e.g., HIPAA for healthcare data, GDPR for global data, though our focus is USA).

- Protected Communication Channels: Use secure VPNs or private networks for remote connections to minimize exposure to public internet threats.

By adhering to these best practices, we can harness the power of remote diagnostics with confidence, knowing our systems and data are well-protected.

The Future of Diagnostics: AI, Predictive Analysis, and Evolving Tech

The journey of remote diagnostic services is far from over; in many ways, it’s just beginning. The capabilities we see today are merely a foundation for an even more intelligent, autonomous, and integrated future. We are on the cusp of an era where systems not only tell us what is wrong but also why it’s wrong, when it’s likely to fail, and even how to fix it before it becomes a problem.

This evolution is largely driven by advancements in artificial intelligence (AI), machine learning (ML), and the continuous development of connectivity and automation technologies. We’re looking at a future where over-the-air updates are standard, and augmented reality might even guide technicians through complex repairs.

The Role of AI and Machine Learning in Remote Diagnostic Services

Artificial Intelligence (AI) and Machine Learning (ML) are the rocket fuel propelling the next generation of remote diagnostic services. While current systems can detect fault codes, AI/ML takes this to a whole new level by adding intelligence and predictive power.

- Anomaly Detection: ML algorithms can analyze vast datasets from sensors and identify subtle deviations from normal operating patterns that human eyes might miss. These anomalies often precede a major failure.

- Predictive Failure Analysis: By learning from historical failure data and current operating conditions, AI can predict when a component is likely to fail, allowing for maintenance to be scheduled precisely when needed, not too early or too late. Companies like Bosch Remote Diagnostics are at the forefront of leveraging AI for proactive issue identification.

- Root Cause Identification: Instead of just reporting a fault, AI can analyze multiple parameters to pinpoint the underlying cause of a problem, saving valuable diagnostic time.

- Automated Recommendations: Based on its analysis, AI can provide automated, intelligent recommendations for repair actions, parts needed, or even remote adjustments, guiding technicians toward the most efficient solution.

AI models can run both on-device and in the cloud, offering a dual approach for immediate diagnostics and long-term analytical insights. This means smarter, faster, and more accurate diagnostics than ever before.

Enabling Proactive and Predictive Maintenance

With AI and ML integrated into remote diagnostic services, we are fundamentally shifting from a reactive “fix-it-when-it-breaks” mentality to a proactive “prevent-it-from-breaking” strategy. This is the essence of proactive and predictive maintenance.

- Shifting from Reactive to Proactive: Instead of waiting for a breakdown to occur, systems can anticipate potential issues, allowing maintenance teams to intervene before problems escalate. This minimizes unexpected downtime and emergency repairs.

- Data-Driven Maintenance Schedules: Maintenance is no longer based on rigid time intervals but on the actual condition and predicted needs of the asset. This optimizes resource allocation and reduces unnecessary service.

- Extending Asset Lifespan: By addressing minor issues promptly and performing maintenance at the optimal time, the overall lifespan of equipment and machinery is significantly extended, maximizing return on investment.

This capability not only saves money and time but also contributes to greater operational stability and reliability across industries. The ability to anticipate and prevent problems is a key benefit, much like how The Key Benefits of Telehealth Services allow for proactive health management.

Conclusion: Embracing a More Connected and Proactive Future

We’ve explored how remote diagnostic services are not just a technological advancement but a fundamental shift in how we approach monitoring, maintenance, and problem-solving across diverse industries. From optimizing trucking fleets and ensuring HVAC efficiency to revolutionizing healthcare, the benefits are clear: reduced downtime, significant cost savings, improved safety, and vastly improved operational efficiency.

By leveraging remote diagnostics, industries from healthcare to manufacturing are opening up unprecedented levels of efficiency and foresight. We’ve seen how continuous monitoring, real-time data analysis, and the power of AI and machine learning are enabling a future where issues are identified and addressed before they even become problems. This proactive approach ensures greater reliability, extends the life of valuable assets, and empowers decision-makers with actionable insights.

For individuals seeking similar accessibility and proactivity in their personal health, modern virtual care provides a powerful solution. Just as remote diagnostics transforms industrial operations, our virtual primary and urgent care services at Synergy Health DPC bring healthcare directly to you, offering unlimited virtual visits, 24/7 provider access, and personalized treatment without the hassle of traditional appointments. Find how you can benefit from immediate virtual urgent care. The future is indeed remote, and it’s brighter, more efficient, and more connected than ever before.